TM 11-5805-356-34-1

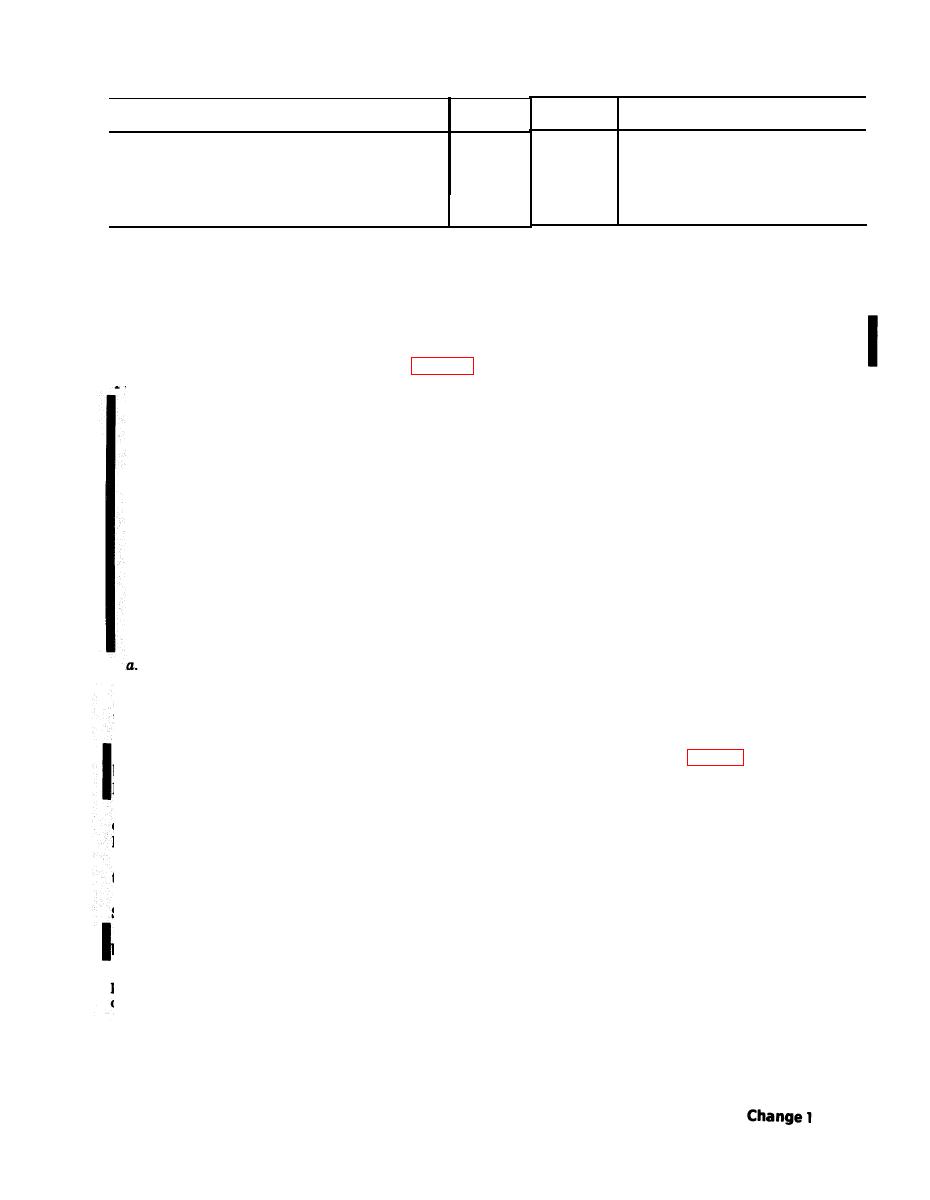

Conditions

Resistance

Terminals

Component

(ohms)

25

1-3

Send card 1A1 removed from unit and ex-

Output transformer 1T3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5

33

ternal lines disconnected.

218

None.

1-3

Oscillator inductor 1A1L1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receive card 1A3 removed.

1-2

90

Discriminator transformer 1Z2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

80

3-6

7-10

80

(1) Remove all power connections from the

TH-22/TG under test.

(2) Operate the 4W-2W-TEL switch to 2W and

priate line terminal connections are established for

the NORM-REC-SEND switch to SEND.

the specified switch settings and strapping connec-

(3) Use AN/PSM-45 to measure resistance

tions. Additional tests within the equipment may be

across 2W-4WR terminals E5 and E6. Resistance

required when troubleshooting. These tests should

should be 100 ohms 10 percent.

be made in accordance with the wiring diagram (fig.

(4) Operate the NORM-REC-SEND switch to

FO-4) after removing the PC boards,

REC.

CAUTION

In making continuity and resistance

minals E5 and E6. No continuity should be indicated.

checks independently without following a

(6) Operate the NORM-REC-SEND switch to

prescribed procedure, make sure not to ap-

NORM.

ply a potential between transistor ele-

(7) Insert the COMBAT link.

ments that could destroy the transistor.

(8) Check for continuity between 2W-4WR ter-

The battery in the AN/PSM-45 can de-

minals E5 and E6. Continuity should be present.

stroy transistors by causing excessive

3-4. Bench Testing

current through them. In some instances,

0.1 volt applied between base and emitter

The direct support maintenance procedures require

in the reverse direction can destroy a sur-

access to the interior of the TH22/TG and, in many

face barrier transistor. Never make any

instances, to points on or below the pc boards. Pro-

continuity checks with power applied to

ceed as follows:

TH-22/TG.

a. Removal of Chassis From Case. Loosen the

Line Facility. Test the connection of the

three camlock screws on the unit front panel by turn-

TH-22/TG to two-wire or four-wire lines as follows:

ing them one-quarter turn counterclockwise; pull the

(1) Remove all power from TH-22/TG under

chassis forward from the case.

test.

b. Removal of Pc Boards.

(2) Operate the 2W-4W-TEL switch to TEL.

(1) Loosen

the three screws on the hinged panel

(3) Use the AN/PSM-45 to check for continuity

at the rear of the chassis (fig. 3-5), and lower the

between terminals E4 and E6, and between E3 and

panel.

E5.

(2) Use the extractor handle to pull out the pc

b. Radio Operation. Test the operation of the cir-

boards from the chassis mounting rails.

cuit closure that provides for radio operation as fol-

c. Adjusting the Pc Boards to Test Position.

lows:

(1) Remove the three pc boards from the chassis

(1) Remove all power from the TH-22/TG under

(b above).

test.

(2) On both sides of the chassis, loosen the

(2) Operate the NORM-REC-SEND switch to

screws that hold the harness board connector mount-

SEND.

ing bracket.

(3) Use the AN/PSM-45 to check for continuity

(3) Rotate the harness board connector bracket

between CONT terminals E1 and E2.

upward so that the slotted centerpiece is straight up.

c. Holding Coil. Determine whether a dc closure is

(4) Reinsert the pc boards in the harness pc

provided through terminals E5 and E6 for two-wire

board connector.

operation, in the sending mode as follows:

Previous Page

Previous Page