TM 11-5805-356-34-1

Section II. TOOLS AND EQUIPMENT

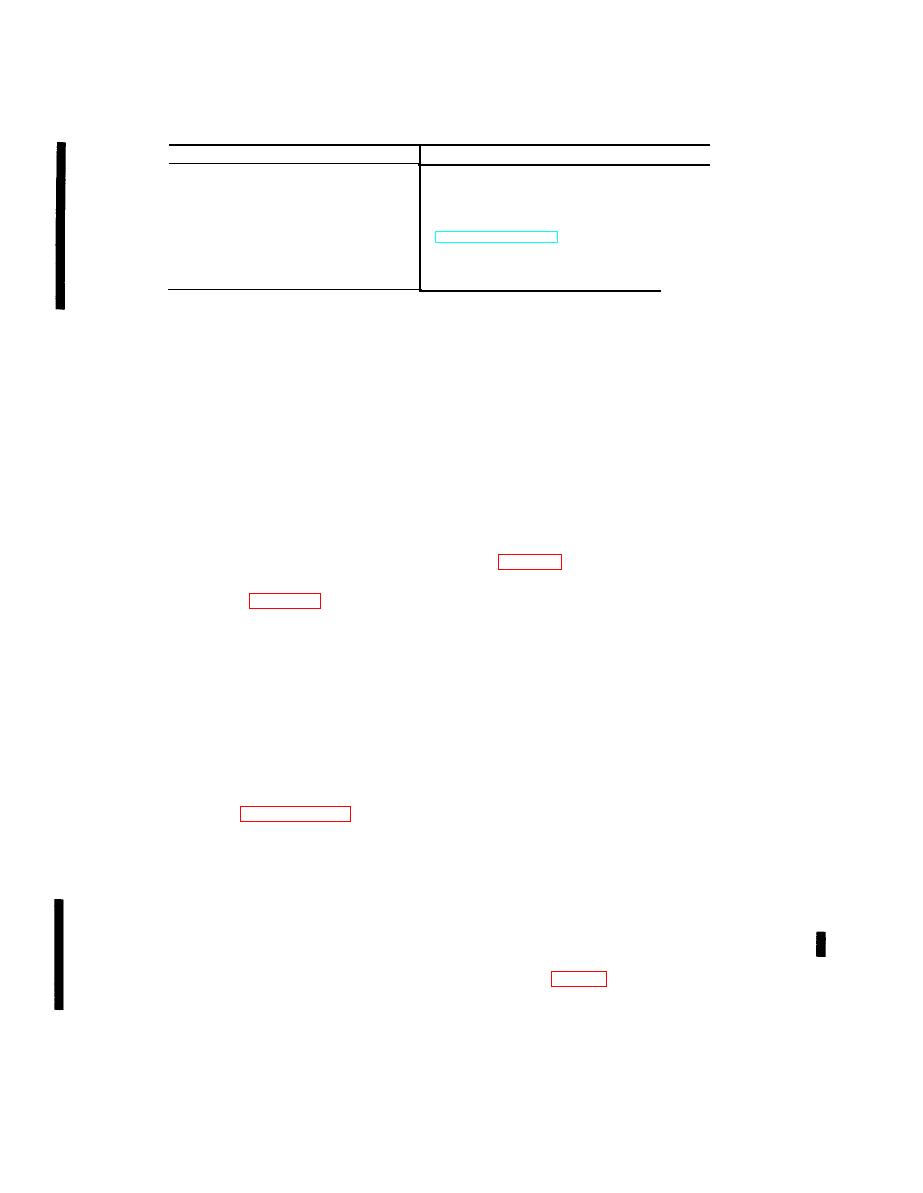

The following chart lists the test equipment and tools required for direct support maintenance.

Test equipment and tools

Associated technical manual

Electronic Counter AN/USM-459

TM 11-6625-700-10

Digital Multimeter AN/PSM-45

No applicable

Digital Multimeter AN/USM-486

Not applicable

Oscilloscope AN/USM-281( )

TM 11-6625-1703-15 or TM 11-6625-2658-14

Telephone Set TA-312/PT

TM 11-5805-201-12

Test Set TS-2/TG

TM 11-2208

Test Set AN/USM-181

TM 11-6625-602-12

Tool Kit, Electronic Equipment TK-105/G

Not applicable

Section III. TROUBLESHOOTING

3-5. Introduction

quence in which they are given. The tests are to be

performed with the TH-22/TG chassis removed from

Trouble in the TH-22/TG is isolated in three stages.

its case. Each test provided an indication that will be

The procedure starts by making operational tests on

obtained when the circuit is operating normally. So

the unit to identify the malfunction, which is then

long as the normal indications are obtained, continue

referred to under a symptom in the troubleshooting

with the operational tests. Upon completion of a test,

chart. The troubleshooting chart lists probable trou-

disconnect the test equipment used before continu-

bles that can cause the noted symptom. Probable

ing with the next test. When a normal indication is

troubles are eliminated, and the trouble causing the

not obtained for one of the tests, locate the symptom

symptom is identified by utilizing additional data

that describes the failure in the troubleshooting

supplied. The additional data comprise voltage and

chart (para 3-7b). Investigate the probable causes

resistance measurements, the schematic diagram,

associated with the noted system and take the cor-

and the wiring diagram. Reference may also be made

rective action for the cause suggested in the chart.

to the circuit descriptions in chapter 2. If the trouble

Upon completion of the corrective action, make sure

is isolated to a chassis mounted part, repairs are

that the trouble has been corrected by repeating the

authorized at the direct support category. If the trou-

operational test and noting that a normal indication

ble is isolated to a printed card or to a part mounted

is now obtained.

on a printed card, the card must be replaced. A nota-

tion should then be made stating the defect for which

a. Power Supply Output Voltage Test.

the card was replaced; this notation should accom-

(1) Operate the TH-22/TG front panel controls

pany the card when it is forwarded to a higher main-

as follows:

tenance category for repair. After completion of re-

NOTE

pairs, the operational tests must be repeated. If any

A control for which no position is specified

adjustments are required as a result of the repair or

may be left in any position.

to correct a trouble, refer to the applicable adjust-

Control

Position

ment procedure given in paragraph 3-8, 3-9 and

ON-OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. OFF

115V AC-230V AC-26 DC

Position corresponding to power

source being used.

NOTE

(2) Connect TH-22/TG to a power source. (Use

Adjustment of the oscillator output fre-

connector P1 for ac power, connector J5 for dc

quency on send card 1A1 is not authorized

power.)

for direct support maintenance. When ad-

(3) Operate the ON-OFF switch to ON.

justment is required, replace send card

(4) Use the AN/PSM-45 (set measure 18 volts

1A1 with an adjusted card, and forward

dc) to measure the voltage between ground and test

the card requiring adjustment to higher

point A1TP2 (fig. 3-7). The meter should indicate

maintenance category with appropriate

+18 volts dc 1.8.

notation.

(5) Repeat (1) through (4) above for the other two

power inputs with which the TH-22/TG can be used.

Perform the following operational tests in the se-

Change 1

Previous Page

Previous Page