TM 11-6625-1668-12

until a new measurement is initiated. In order to initiate a new measurement set the RESET switch to MAN and

release to the OFF position. Normally during error rate measurement the RESET switch is operated in the

MAN and OFF positions to allow sufficient time for a complete measurement. Operation in the AUTO position

is not recommended as the auto reset period of 3 to 5 seconds will only allow measurement for one thousand

bit times above 600 baud. The nixie display is limited to a maximum error rate of 99 errors per thousand or

million bit times. When this limit is reached the OVERFLOW lamp illuminates and the number of errors

displayed becomes invalid. The time required to complete an error rate measurement depends on the

operating speed of the analyzers. Each operating speed and the total time required to complete a thousand or

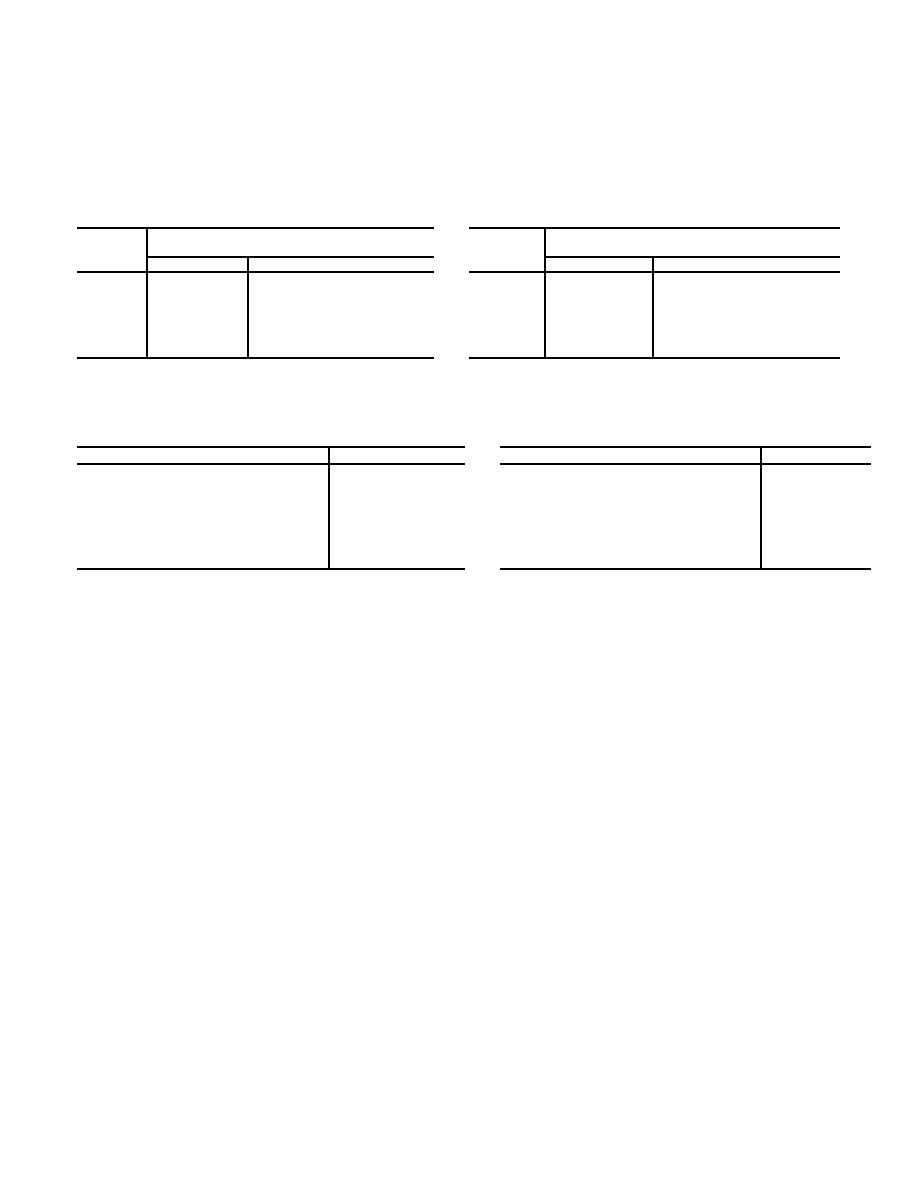

million bit time measurement is listed as follows:

Operating

Time required to complete error rate measurement

Operating

Time required to complete error rate measurement

speed in

speed in

3

6

3

6

bauds

10 bit times

10 bit times

bauds

10 bit times

10 bit times

37.5

26-2/3 seconds

7 hrs 24 min 26-2/3 secs

300

3-1/3 seconds

55 min 33-1/3 secs

45.45

22 seconds

6 hrs 6 min 40 secs

600

1-2/3 seconds

27 min 46-2/3 secs

50

20 seconds

5 hrs 33 min

1200

5/6 seconds

13 min 53-1/3 secs

61.12

16-2/5 seconds

4 hr 33 min 20 secs

2400

5/12 seconds

6 min 66-2/3 secs

75

13-1/3 seconds

3 hrs 42 min 13-1/3 secs

43 00

6/24 seconds

3 min 23-1/3 secs

150

6-2/3 seconds

1 hr 51 min 6-2/3 secs

9600

6/43 seconds

1 min 44-1/16 secs

(6) Typical operation ERROR RATE. For the purpose of this procedure two analyzers are required;

one for transmitting and the other for receiving. The transmitting analyzer pseudo-random output (6 volts,

MIL STD 188B) at 2A3J3 pins 3 (data) and 24 (ground) is connected to the bridging input of the receiving

analyzer. The initial control settings are listed below:

Control

Position

Control

Position

POWER switches (transmit and

OFF

ERROR DEFINER thumbwheels

49 or 00

receive). ..........................................

(receive). ......................................

DISPLAY MODE switch (transmit) ...

TEST MODE

BAUD RATE switch (transmit and

600

receive). .......................................

ERROR RATE 103

DISPLAY MODE switch (receive) .....

INPUT switch (receive) ................

HIZ

CODE LEVEL switch (transmit) .......

SYNC

MARK POLARITY (receive) ..........

- (negative)

NOTE

The position of unmentioned controls will not affect operation in this mode.

(a) Set the POWER switches to ON and reset the nixie display.

(b) Read error rate per 1000 bit intervals on the nixie display when the measurement period is

complete. Errors counted have exceeded one percent distortion.

NOTE

The measurement period begins when the SPACE/START lamp illuminates and ends when

the MARK/FINISH lamp illuminates. The overflow lamp illuminates when the total number

of errors exceeds 99.

(c) Set the DISPLAY MODE switch to 106, reset the nixies and read error rate per 1,000,000 bit

intervals.

(7) PEAK MON. The analyzer is used as a distortion monitor when the DISPLAY MODE switch is set

to PEAK MON (HITS). In this operating mode the analyzer becomes a full period peak monitor registering on

the nixie display, one hit for every M/S or S/M transition that exceeds a preset distortion threshold. When peak

hits are counted, distortion measurement in the analyzer are made as usual except that the distortion measure-

ment is no longer displayed. In place of the distortion reading, the nixie display indicates the number of times

the preset distortion threshold has been exceeded (hits). The distortion threshold is established by the setting

of the THRESHOLD % DISTORTION thumbwheel switches. The threshold is set for the maximum permissible

distortion in 1 percent increments from 00 to 49. Peak hits are detected by comparing the actual distortion

present on the data signal with the distortion setting of the thumbwheels. When the actual distortion on the

circuit under test is greater than the threshold setting a hit is counted, and the nixie display is updated. If, how-

ever, the distortion is equal to or less than the setting of the thumbwheels, hits are not counted and the nixie

display remains unchanged. The highest number that can be displayed on the nixie readout is 99. Therefore

when the number of hits counted reaches 99 the nixie display begins counting from 00 again and the OVER-

FLOW lamp illuminates. Peak measurements are made with RESET switch in the OFF position. If this switch

is set to AUTO the peak hit measurement is interrupted every 3 to 5 seconds. To reset or destroy old peak hit

readings set the RESET switch to MAN and release to the OFF position. This allows the analyzer to make a

new peak hit measurement.

3-17

Previous Page

Previous Page