TM 11-6625-1668-12

Control

Position

Control

Position

CHARACTER LENGTH switch .........

8

ALARM switch..................................

DISABLE

SINGLE switch ................................

(Not used)

BAUD RATE switch..........................

1200

OSC switch .....................................

INT

(a) Connect a patch cord from the DATA 6V OUTPUT jack of the generator to the BRIDGING

INPUT jack of the analyzer.

(c) The analyzer nixie display will indicate 25% l% and the MARK lamp will illuminate to indicate

marking bias.

(d) Change the PERCENT DISTORTION switch on the generator to 20%; the analyzer nixie

display will indicate 20% 1% and the MARK lamp will illuminate to indicate marking bias.

b. Analyzer Modes of Operation. The analyzer is designed to provide four modes of operation; TEST

MODE, DISTORTION, ERROR RATE, and PEAK MON.

(1) Test mode. The analyzer, when operated in conjunction with the generator, will produce a pseudo-

random test pattern. This test pattern is applied to the generator through the rear panel connector and back to

the analyzer for system self-test. The system self-test is performed as part of the maintenance procedures.

This function is accomplished when the analyzer DISPLAY MODE switch is set to TEST MODE and when the

generator MESSAGE SELECT switch is set to EXT. The BAUD RATE switches of both units must be the same

and the interface cable CX-12024/GGM-15(V) must be connected. Refer paragraph 4-8 for a detailed

explanation test mode operation.

(2) Typical operation TEST MODE. The purpose of this operating procedure is to test the analyzer

error code operation. To perform the error test operation a generator (SG-860/GGM-15(V)) is required and

must be connected to the analyzer through the interface cable. The initial control settings of the generator and

analyzer are listed below.

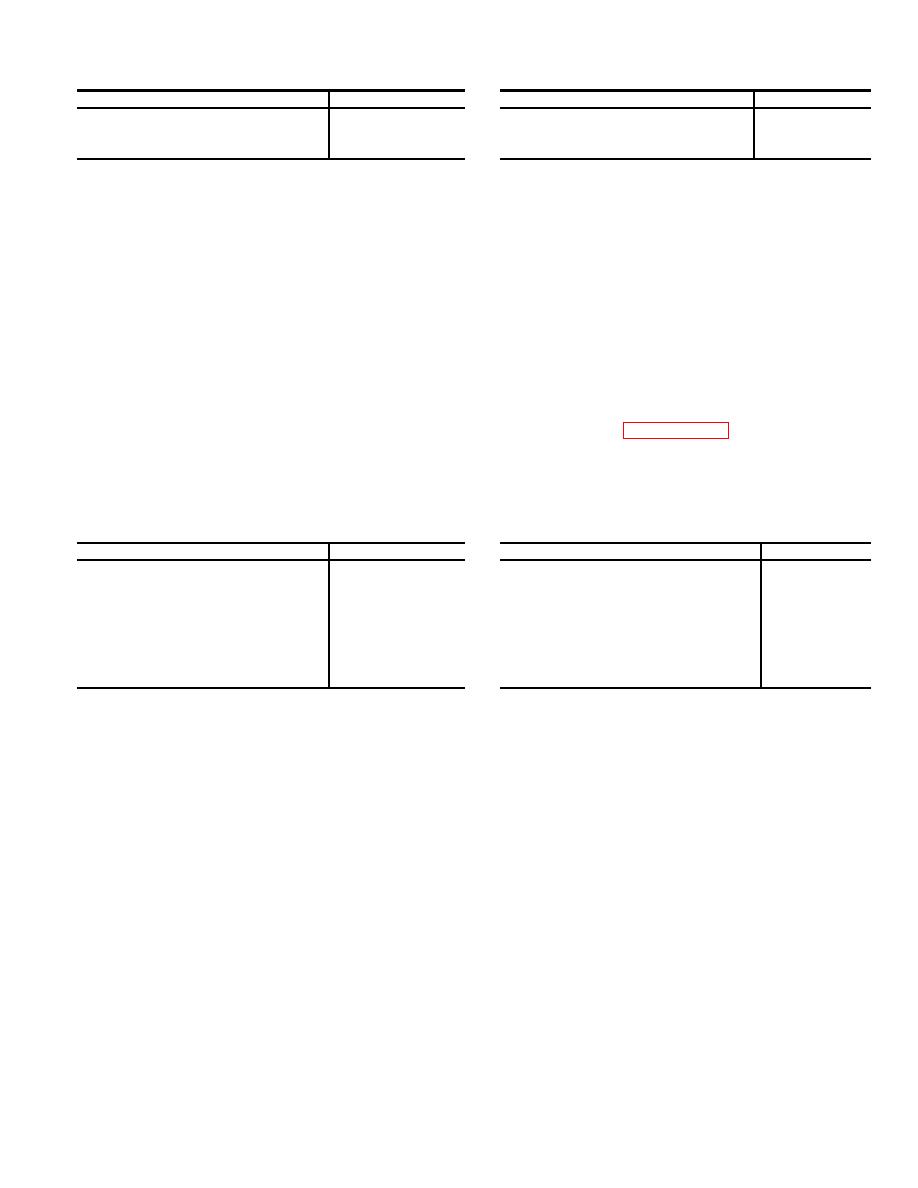

Control

Position

Control

Position

POWER switches (analyzer and

OFF

MARK POLARITY switch (analyzer) .....

.....................

generator).

DISTORTION SELECT switch

NO DIST

RESET switch (analyzer)......................

OFF

(generator).

MESSAGE SELECT switch

EXT

DISPLAY MODE (analyzer) ..................

TEST MODE

(generator).

BAUD RATE switches (analyzer and

120

ERROR DEFINER thumbwheels ..........

49

generator).

NOTE

The position of unmentioned controls will not effect error test operation.

(a) Set the POWER switches (generator and analyzer) to ON.

(b) Depress the RESET switch to MAN and release it. Read approximately 10 errors every 9

seconds and note an overflow indication after 98.

(c) Set the generator DISTORTION SELECT switch to BIAS M and the PERCENT DISTORTION

switches to 25.

(d) Reduce the setting of the ERROR thumbwheel switches to the point where the nixies display a

rapid count.

(e) Read the amount of distortion on any M/S or S/M transition as indicated by the number on the

thumbwheel switches.

(3) DIST (%). The analyzer is used to measure distortion on data or telegraph signals when the

DISPLAY MODE switch is set to DIST (%). Distortion, as measured by the analyzer is defined as the time

displacement of a signal transition from its theoretically correct position. The transition is taken as the half-

current point, for neutral signals and is the zero current crossover point for polar signals. The analyzer is used

to measure bias, end, total, early and late peak distortion. Characteristic, fortuitous, and speed-error distortion

are determined from these measurements. When making an analysis the operator should first determine the

baud rate, type of signal (polar or neutral) current level, and operating mode (start-stop or synchronous). The

amount of bias and end distortion is read directly on the nixie display while the MARK and SPACE lamps

indicate the type. When total-early or late-peak measurements are made the MARK and SPACE lamps are

inoperative. However, an early-peak reading indicates the presence of marking distortion and a late-peak

3-15

Previous Page

Previous Page