TM 11-6625-1668-12

reading indicates the presence of spacing distortion. Both early and late readings indicate the presence of

fortuitous distortion. To quickly determine the peak distortion without regard to early or late measurements, the

DISTORTION switch is set to TOTAL. The amount of speed distortion is determined by measuring the

distortion on successive transitions. The distortion measurement increases on each successive transition. A

faster incoming signal will introduce marking bias and a slower incoming signal will introduce spacing bias.

(4) Typical operation, DIST. For the purpose of this example assume the following analyzer input

signal characteristics; 60 volts polar at 20 ma, 150 bauds, positive mark, 1:1 reversals, 25 percent distortion

(marking bias). Initial analyzer control settings are listed below.

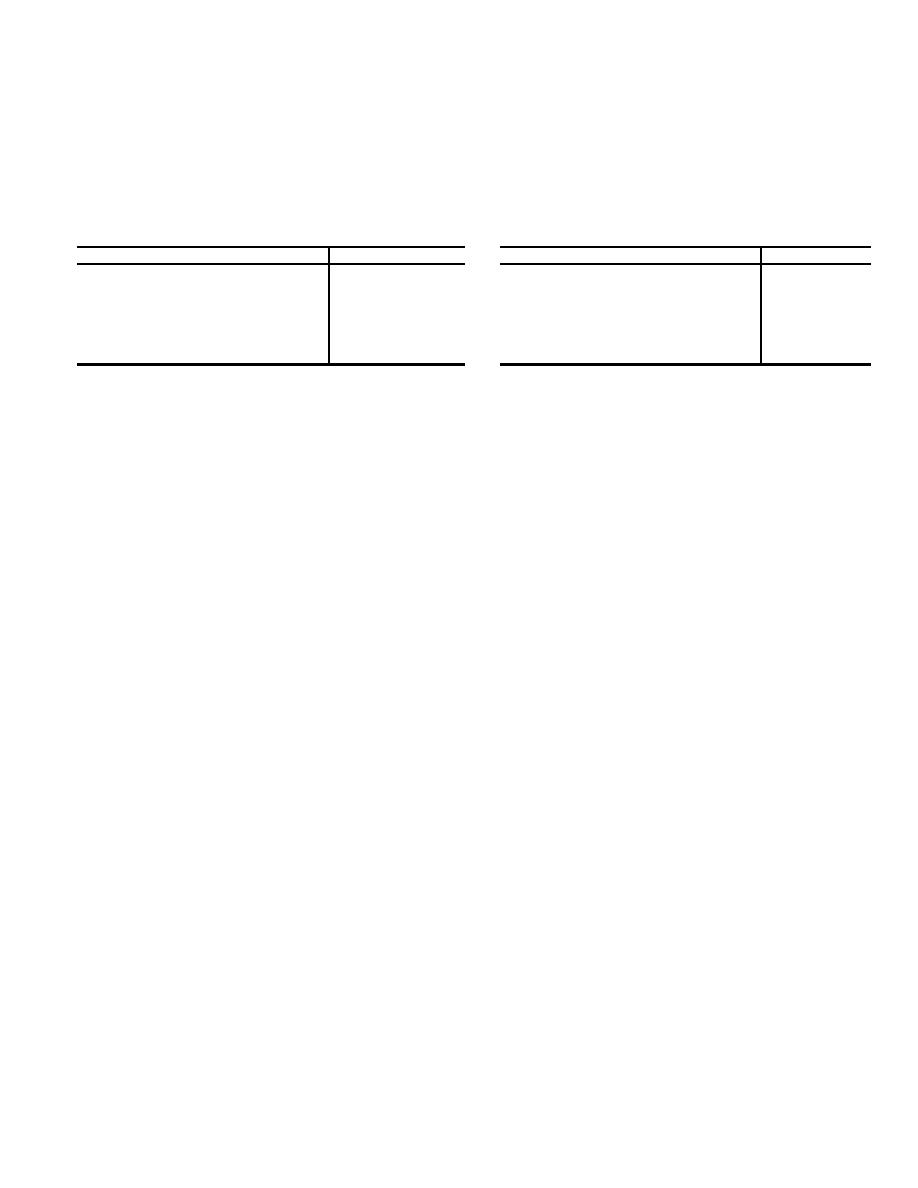

Control

Position

Control

Position

POWER switch..................................

OFF

INPUT switch .......................................

20P

MARK POLARITY switch ...................

+

TRANSITION switch ............................

ALL

RESET switch....................................

OFF

DISTORTION switch ............................

AVERAGE

BIAS S/M

DISPLAY MODE switch .....................

DIST (%)

BAUD RATE switch..............................

150

CODE LEVEL switch .........................

5

NOTE

The position of unmentioned controls will not affect operation in this mode.

(a)

Connect the external data signal to the analyzer SERIES input jack.

(b)

Set the POWER switch to ON.

Reset the nixie display and read 25 percent average marking bias distortion 2 percent.

(c)

(d)

Set the TRANSITION switch to 1 and read 25 percent marking bias on the first intelligence bit

2 percent.

(e) Sequentially select transitions 2, 3, 4, 5 and read the amount of bias distortion on each

intelligence bit. (Odd numbered transitions are distorted, even numbered transitions do not appear on the data

signal.)

(f) Set the TRANSITION switch to ALL, the DISTORTION switch to AVERAGE END M/S, reset the

nixie display and read 0 average end distortion 2 percent.

(g) Set the DISTORTION switch to PEAK TOTAL, reset the nixie display and measure 25 percent

total peak distortion 2%.

(h) Set the DISTORTION switch to EARLY, reset the nixie and read 25 percent early peak

distortion 2 percent.

(i) Set the DISTORTION switch to LATE, reset the nixie display and read 0 percent late peak

distortion- 2 percent.

(5) ERROR RATE (Hits/10n). The analyzer is used to measure error rate on a 2047 bit pseudo-random

test message. The rate is displayed as errors per thousand or million bit times. The message is generated

within the analyzer and is available at the rear panel connector 2A3J3. The data output is supplied at 6 volts

at pin 8, and its return at pin 24. To measure error rate two analyzers are required, one for transmitting the

message and one for receiving and analysis. For normal operation, the transmitting analyzer controls are set

as follows: POWER to ON, DISPLAY MODE to TEST MODE, CODE LEVEL to SYNC, RESET to OFF and

BAUD RATE to the desired operating speed. The receiving analyzer controls are set as follows: POWER to

3

6

ON, DISPLAY MODE to ERROR RATE 10 or 10 , ERROR DEFINER to the maximum permissable distortion

percentage. RESET to OFF and BAUD RATE to the same speed as the transmitting analyzer. The input

connection is made to either the SERIES or BRIDGING input jacks on the receive analyzer front panel. The

INPUT switch is set to the position that corresponds with the input signal level. The positions of the

unmentioned controls will not affect operation in this mode.

The correct position of the MARK POLARITY switch is determined by setting the RESET switch to MAN and

releasing to the OFF position. If the SPACE/START lamp illuminates the mark polarity is correct. If this lamp

does not illuminate, set the MARK POLARITY switch to the opposite polarity and operate the RESET switch as

previously described. The SPACE/START lamp will illuminate when the internal and external pseudo-random

test messages are synchronized, and remain illuminated until the measurement period is completed.

When synchronization occurs the analyzer begins to count errors and will stop counting only when the period of

measurement for a thousand or million bit times has elapsed. At this point the MARK-STOP lamp illuminates

and the number displayed on the nixie readout indicates error rate. This number (error rate) remains displayed

3-16

Previous Page

Previous Page