TM 9-2320-269-20-1

ORGANIZATIONAL TROUBLESHOOTING - CONTINUED

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

AIR SYSTEM AND BRAKES - CONTINUED

BRAKES RESPOND SLOWLY OR NOT AT ALL - CONTINUED

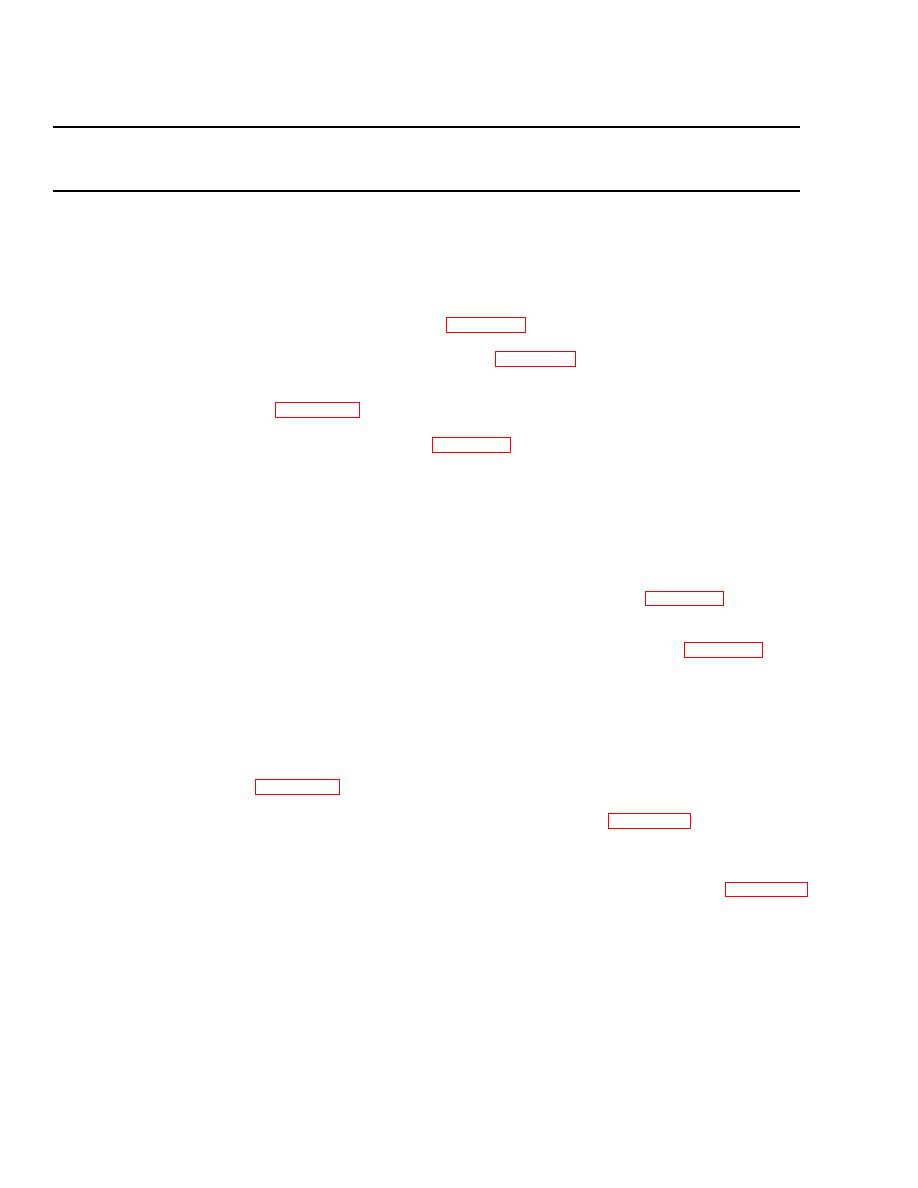

Step 2. Inspect brake assembly for binding parts.

a. Remove hub and drum assembly (page 2-611).

b. If parts are damaged, replace as needed (page 2-611).

c. If shoes (1), springs (2), or anchors (3) are tight, lubricate (LO 9-2320-269-12) or replace as

needed (page 2-478).

d. Install hub and drum assembly (page 2-611).

Step 3. Inspect brake chambers (4) for damage and leakage.

a. Start engine (TM 9-2320-269-10), let air pressure build up, and shut off engine (TM 9-2320-269-

10).

b. Coat brake chamber (4) with soap solution, have assistant apply brakes, and hold.

c. If brake chamber (4) shows signs of leakage or damage, replace (page 2-492), or notify Direct

Support Maintenance.

d. If pushrod (5) is dirty or damaged, clean or replace brake chamber (4) (page 2-492), or notify

Direct Support Maintenance.

e. Release brakes.

Step 4. Inspect brake hoses (6) for damage.

a. If hoses (6) are bent or pinched between vehicle components, remove and reroute, or replace as

needed (page 2-567).

b. If hoses (6) are damaged or collapsed, replace as needed (page 2-567).

Step 5. Inspect brake valves (7) for damaged and loose parts.

a. If valves (7) are damaged, replace using applicable maintenance procedure (page 2-477).

b. If hoses (6) or fittings (8) are loose, tighten as needed.

2-104

Previous Page

Previous Page