TM 9-2320-269-20-1

ORGANIZATIONAL TROUBLESHOOTING - CONTINUED

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

ENGINE - CONTINUED

RUNS UNEVENLY - SURGES, STALLS, OR NO POWER - CONTINUED

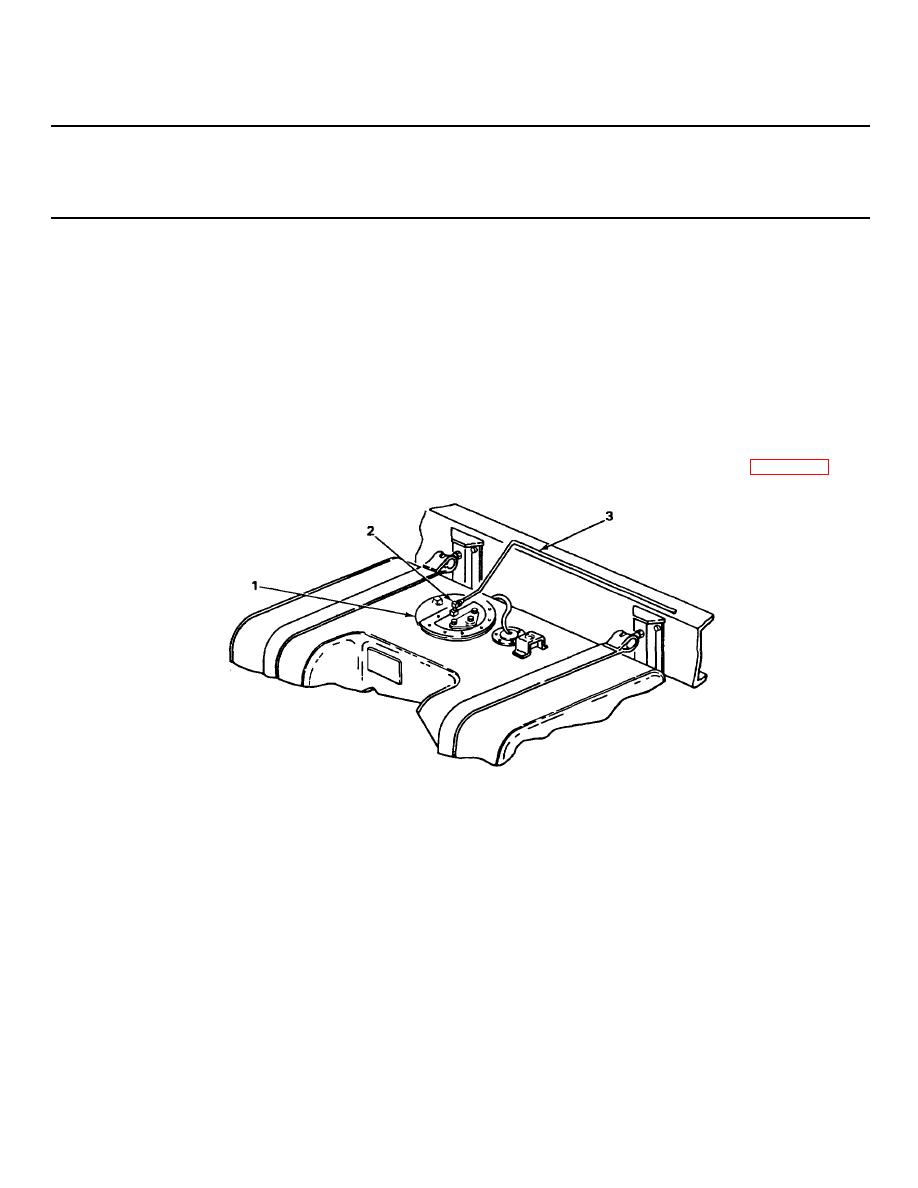

Step 6. Test in-tank fuel pump (1) pressure.

a. Install in-line pressure gage between pump fitting (2) and line (3) using 3/4-inch

and 5/8-inch wrenches.

b. Have assistant crank engine, check gage reading, and remove gage using 3/4-

inch and 5/8-inch wrenches.

c. If gage reads lower than 3 to 5 psi (21 to 35 kPa), remove pump (1) (page 2-

167) and clean or get rid of. Install new pump (1) as needed (page 2-167).

Step 7. Test fuel supply lines (3), (4), and (5) for blockage.

a. If any lines (3), (4), and (5) are damaged, replace using 3/4-inch and 5/8-inch

wrenches as needed.

b. Install in-line pressure gage between each line (3), (4), and (5), and filters (6)

and (7) at fittings (8 thru 12) one at a time. Have assistant crank engine, check

gage reading, and remove gage using 3/4-inch and 5/8-inch wrenches.

TA228594

2-68

Previous Page

Previous Page