TM 11-5805-587-15/3

TO 31W2-1-471-3

CHAPTER 4

ON-SITE MAINTENANCE

GENERAL REQUIREMENTS

Section I.

scope.

This chapter contains the information needed to perform preventive

The tools, test

and corrective maintenance on the TSC equipment.

equipment, a n d m a t e r i a l s r e q u i r e d f o r m a i n t e n a n c e a r e l i s t e d i n t h i s

Section II defines the checks and service periods and out-

section,

Sections

lines the procedures for performing preventive maintenance,

III through XI contain the procedures for making physical tests and

inspections and for checking the operating capability of the finder,

elector, register-sender, translator, trunk, transmission, switch-

board, miscellaneous, and alarm equipments, respectively.

XII describes the strapping fields and the manner in which they are

Section XIII contains the alignment

used to program the translator.

Relay adjustments and tests and the relay adjustment

procedures.

Section XV outlines the proce-

tables are contained in Section XIV.

The

dures for testing and repairing printed circuit (PC) cards,

Section XVII

system troubleshooting charts appear in Section XVI.

contains repair and adjustment instructions. These consists of re-

moval, r e p l a c e m e n t , d i s a s s e m b l y , a n d r e a s s e m b l y i n s t r u c t i o n s a n d a d -

Section XVII con-

justment and alignment of mechanical assemblies.

tains repainting, refinishing, and lubrication instructions.

Tools, Equipment, and Materials Required.

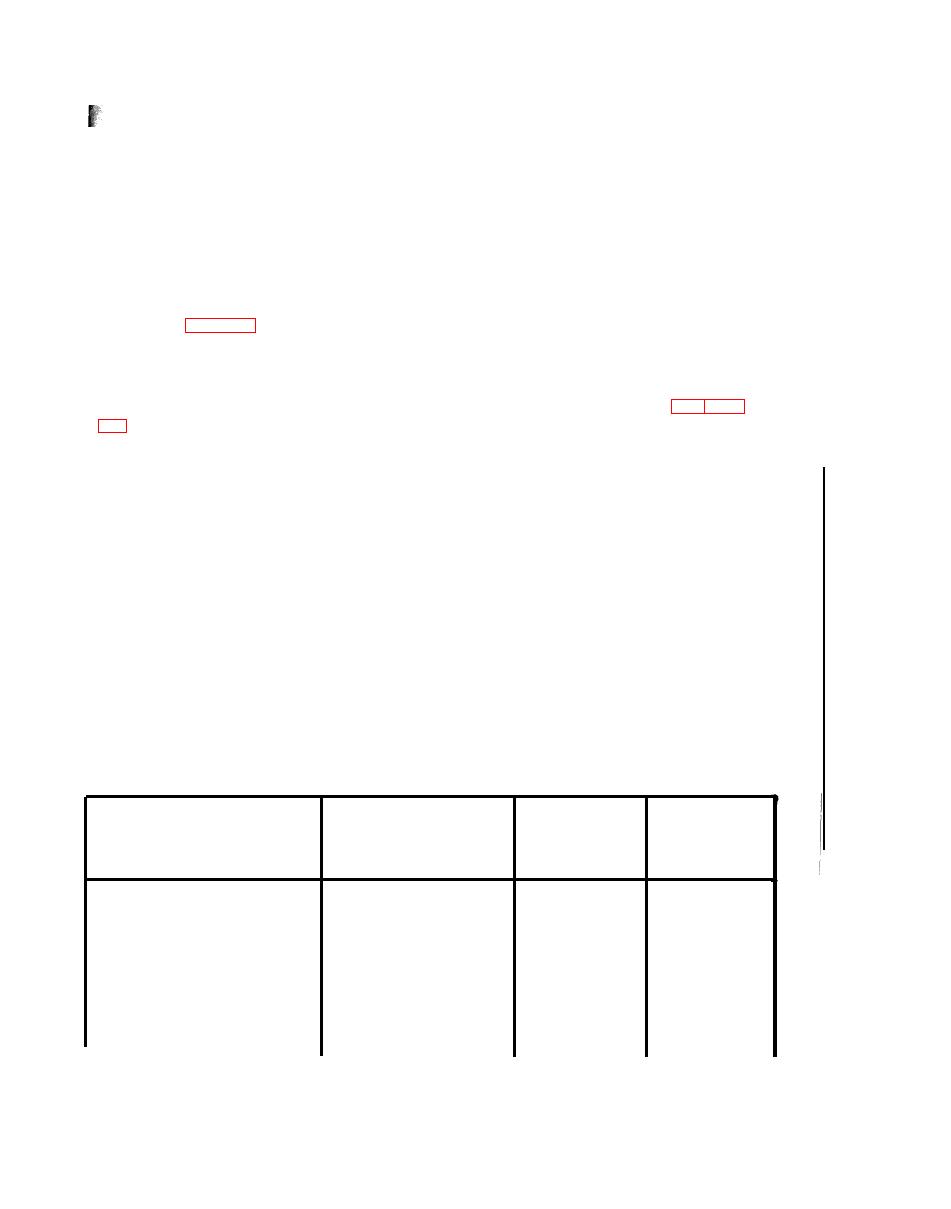

The tools, equipment, and materials required for TSC maintenance

These tables include columns

are listed in Tables 4-1 through 4-3.

for item description, manufacturer, part number, and, where appli-

Table 4-l lists the standard tools

cable,

federal

stock

number.

Table

and equipment.

Table 4-2 lists special tools and equipment.

4-3 lists the materials.

Standard Tools and Equipment

Table 4-1.

Federal

stock

no.

Description

Manufacturer

Part no.

Ac Voltmeter

Hewlett-Packard

403B

Hewlett-Packard

AN/USM-140

Signal Generator

Hewlett-Packard

20OCD

Current Flow Test Set

485826-000

Stromberg-Carlson

Digit Display Test Set

Stromberg-Carlson

457071-018

Previous Page

Previous Page